Draft Accuracy of Geometry

This function can be used to refine the faceting of a part, where the rectangular and triangular faces formed by the facet lines are used to make the contours as close to the actual object as possible.

The program will first facet the volume with a value that it assumes appropriate. This can be refined if needed. The starting point for faceting when creating a face is the default value of the face's portions, based on which the program will create the default faceting.

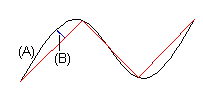

You can achieve the exact shape of the face (A) by reducing the tolerance value (B) and the angle tolerance value. The angle tolerance affects the mesh formed by triangular faces on rounded surfaces. If you decrease the angle tolerance value, the number of triangles increases and the shape of the surface becomes more detailed.

When cutting up a volume, the program will again facet the volume with a calculated value that it assumes appropriate (default faceting), even if you have refined the faceting.

A small tolerance value will make the

model slower to handle. Due to this, you should perform the faceting after finishing the

model.

A small tolerance value will make the

model slower to handle. Due to this, you should perform the faceting after finishing the

model.

Find the appropriate draft accuracy by trying out several different values.

- Select View | Settings |

Draft Accuracy.

Draft Accuracy.

If you select this function in an assembly model, you can select parts or all of the parts with the middle mouse button.

In an assembly model, the draft

accuracy affects only the local parts. Specify the draft accuracy using the tolerance

value.

In an assembly model, the draft

accuracy affects only the local parts. Specify the draft accuracy using the tolerance

value. - Define the geometry drafting properties in the dialog box

- Specify the Tolerance and click Apply.

- Refine the draft accuracy by reducing the tolerance value, for example to 0.1 or 0.01.

- If you wish to have a coarser draft accuracy, increase the tolerance value, for example to 1 or 10.

- Specify the Angle Tolerance and click

Apply.

- Refine the shape of a rounded surface by reducing the tolerance value, for example to 0.1 or 0.01.

- If you wish a rounded surface to have a coarser shape increase the tolerance value, for example to 1 or 10.

- The program calculates default faceting when you set both Tolerance and Angle Tolerance to 0.

- If you select

Save, the draft accuracy values are saved in the part and

faceting will always be done when performing an operation.

Save, the draft accuracy values are saved in the part and

faceting will always be done when performing an operation. - If you do not select

Save, the values last used for faceting will be shown as the

draft accuracy values.

Save, the values last used for faceting will be shown as the

draft accuracy values.

- Specify the Tolerance and click Apply.

- Confirm the data.

Note

Note

- The overall dimensions of the volume affect the calculation of default faceting.

- The draft accuracy of a part is determined based on the part's overall dimensions, from the largest dimension in the direction of the main axes (X, Y or Z). The draft accuracy will be this dimension / 1000.

- The angle tolerance is 1/16 of a full circle, or 22.5 degrees.

- To check the ACIS eligibility of the part in the model window, press Shift+C. After confirming the draft accuracy data, the program will display a list of the geometry elements on the volume and any possible error messages before the list of elements. If there are any error messages, the volume is not ACIS eligible.