Flatten

Sheet-Metal Design

You can be flatten a bent sheet metal part in a model window. Flattening will take into account the strain of the sheet in accordance with the calculation method selected.

Note: If the face to be flattened is a ruled face, flattening will not take into account the strain of the sheet.

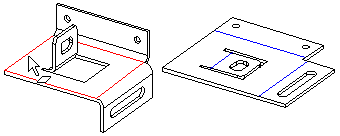

In the corner opening function a flattening in the 3D model is necessary. It is very useful when positioning machined features, which is difficult or impossible when the sheet is bent. Avoid flattening and rebending a model for any other reason, because it can disrupt the model's geometry and make it unusable.

Flatten as follows:

-

Select Sheet metal part | Tools |

Unbend.

Unbend. - (OR) Select the context-sensitive function .

- Select the face based on which the flattening will be made. The program automatically suggests the largest planar surface as the flattening reference surface. Accept the selection by selecting the context-sensitive function

OK or by pressing the middle mouse button or select a new planar surface.

OK or by pressing the middle mouse button or select a new planar surface. - If you have selected BendTable or K-Factor as the stretch calculation method, fill in the data in the Bend Properties dialog box. Select OK.

Note:

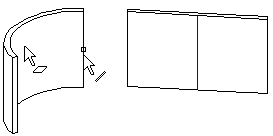

- If the sheet-metal part is formed by a cylindrical face (ruled face), select a sheet end from the face that is to be fastened and remain in place during the flattening.

Figure 2: The side that is to remain in place when flattened is selected from a cylindrical surface. - The strain calculation method is a sheet metal part property which you can redefine by clicking selecting the part and the context-sensitive function

Properties.

Properties. - The flattening of a ruled face will not take into account the strain of the sheet. If the flattening of a ruled face fails, you can make the tolerance value larger. A ruled face which is flattened can not be rebent.

- If you make changes to the sheet, you can rebend it by selecting the function

Rebend.

Rebend. - You can add a flattened view to a drawing by selecting flattening as one of the projections of the drawing. Flattening Drawing

- Every configuration of a sheet metal part can have its own flattening.

Unbend

Unbend