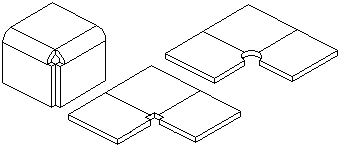

Model a Sheet-Metal Part

Sheet-Metal Design

You can begin modeling a sheet-metal part with a sketch-based thin feature which is a quick way of producing profile-type models. Alternatively, you can create the geometry by modeling a volume and creating a shell structure from it, or add a box-type volume as a library feature.

You can make a sheet-like addition to an edge, which takes take-ins and side angles into consideration. You can add a bend at a sketch line drawn on a face. Flattening the model will take into account the strain in accordance with the calculation method. In the flattened state, you can use library features to punch through the bending area, too. There is a large selection of pre-made sheet-metal features. You can also easily create a flattening drawing, associated with the 3D model, from the sheet.

You can also use the tools flexibly to handle the geometry of imported models that does not contain a modeling history. Flattening a volume and changing the bend radius, bend angle and sheet thickness, and removing features, is easy. You can continue modeling by punching or bending.

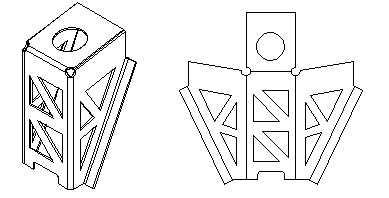

Edge trim

There are tools for trimming edges which allow you to trim the sheet edges (including those in the same plane) to each other or on top of each other. Trim the sheet in the bent state of the model.

Trimming a Corner

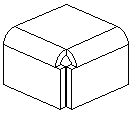

Open corners in the flattened state of the model. The opening tools are parametric and generate shapes that can be rebent. In addition to circular and square openings, the opening shapes in the feature library are available.

Open a round corner in the bent sheet. You can select several faces connected to the round corner at once. The corner opening is also visible in the 3D flattening.