Define the Reference Constraints for a Part

General

- Parts that are going to be positioned together in an assembly with reference constraints must, as a rule, have constraint sets with the same name so that the constraints of the sets can meet.

- When a part is added to the assembly and a part without a constraint set is specified, the program recognizes the element under the cursor and its shape and tries to create a constraint according to the constraint set.

- This way, for example, the bearing can be placed on the shaft without having to make a constraint set for the shaft.

- There may be several constraint sets in a part.

- Each constraint set in one part or assembly must have a unique name.

Define the Reference Constraints

- In the part’s feature tree, right-click Reference Constraints.

- Select New.

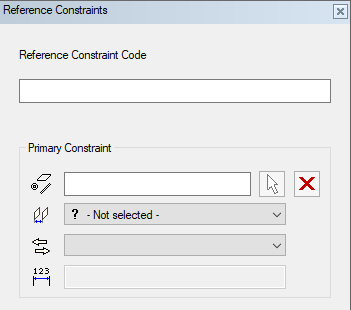

- Enter the Reference Constraint Code.

- The constraint code must be the same for all parts

- Select the Primary Constraint by clicking the arrow button and click an element in the model.

- Select the geometric constraint from the list.

- Select the constraint's direction from the list.

- It is often worth settling for the default direction offered by the program and trying to see if it works.

- If you selected a distance constraint, enter the value of the distance.

- Define the secondary and third constraint in the same way.

Note: The constraints are in mutual order. If a constraint is saved in such a way that the constraint preceding the specified constraint is missing, the constraints are saved in order ignoring the empty constraints.