Split a Large Sheet Surface to Sheet Blanks

Sheet-Metal Design

General

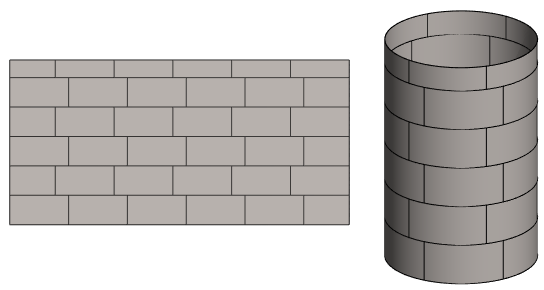

- The split line feature can be used to create sheet splitting for a sheet metal part.

- For example, a tank built from several sheet blanks is modeled as a single model. The sheet seams are displayed for positioning through holes.

- The advantage of this method compared to creating actual welding grooves, for example by a cutout extrusion, is that the model can still be bent and flattened even after the faces have been divided, both during modeling and for the model drawing.

Starting point

- The part is a large cylindrical sheet metal part.

- The part is 3D-flattened.

Create sheet splitting during modeling when the model is flattened as follows:

- Add a new sketch to the face of the part.

- Sketch split lines on the surface of the sheet

- Sketch the lines at the points where there will be welding seams between the bent steel sheets.

- Stop sketching and select an operation.

- Select the ribbon bar function Sketch | Return |

OK or

OK or - Select the context-sensitive function

OK.

OK.

- Select the ribbon bar function Sketch | Return |

- Select

Split Line as the operation.

Split Line as the operation. - Select the surfaces that you want to split with the line in the Selected Elements 1 section.

- By default, the sketch surface is split.

- You can select all surfaces by selecting the context-sensitive function

All in the list.

All in the list.

- Select OK.

- Rebend the model back into a 3D model.

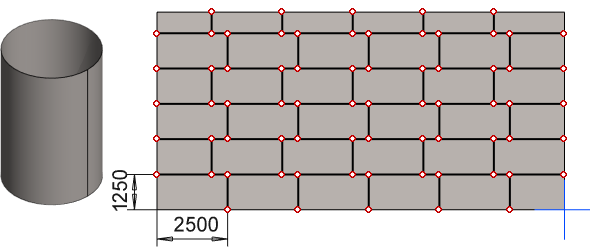

Example, a large tank

- The height of the tank is 7m and the diameter is 4.6m.

- The shell of the tank has been cut.

- The shell has been flattened.

- The size of the steel sheets (1250*2500mm) has been sketched on the surface of the sheet.

- The Split Line has been used as the operation.

- The sheet has been rebent.

- The lines can be used to outline the placement of the sheet blanks.

- By modifying the sketch of the Split Line, possible tank through-holes can be adjusted to the desired points.