Edit Parts with Other Parts - Welding Groove

You can fit parts together in an assembly.

For example, a standard welding groove can be added between sheet metal parts with the Boolean function.

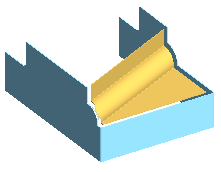

An example of editing with parts.

- The starting point is an assembly model, which includes the following:

- Jig part

- Finished plate section modeled with the Jig.

- Jig part

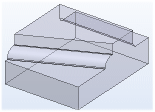

- Select the context-sensitive function New Part, and name the part.

- Select the context-sensitive function Copy Surface.

- Select the Tangential Shelling search.

- Select the face.

- Select Confirm.

- Define the properties in the Copying a Face dialog box.

In is selected.

In is selected.- Select

To Volume.

To Volume.

- Select OK.

- Define the properties in the Surface Chain Data dialog box.

Change to Sheet Metal Part is selected.

Change to Sheet Metal Part is selected.- Define the sheet thickness.

- Select the material by clicking the Select button.

- Select OK.

- Exit the part modeling mode. Select Confirm.

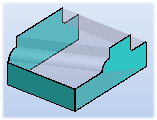

You can hide the Jig part to see the new part in more detail. Select the part and press the H key.

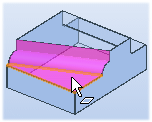

- When nothing is selected, select the context-sensitive function Boolean.

- Define in the Boolean dialog box.

- Operation Subtract.

- Offset Value - In the example, the offset value defines the welding groove. Enter the value. The welding groove is a smaller volume than the plate part.

- Select

Only the Biggest Volume Stays.

Only the Biggest Volume Stays. - Editable Parts - Select the part to be edited. Click the Add button and select a part from the model. Select Confirm.

- Tool Parts - Select the the tool part. Click the Add button and select a part from the model. Preview by clicking the Apply button. Select Confirm.

- Select OK.